Working Hours : Mon - Sat 10:00 am to 7:00 pm

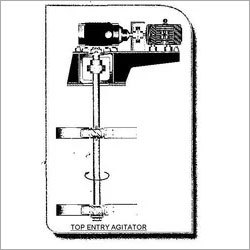

Top Entry Up Agitators

25000 INR

Product Details:

- Power Supply Electric

- Usage Laboratory

- Color Black

- Voltage 220-240 Volt (v)

- Material Stainless Steel

- Warranty 1 Year

- Click to view more

X

Top Entry Up Agitators Price And Quantity

- 25000 INR

- 1 Unit

Top Entry Up Agitators Product Specifications

- 220-240 Volt (v)

- Electric

- Black

- Laboratory

- 1 Year

- Stainless Steel

Top Entry Up Agitators Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 10 Unit Per Day

- 3 Week

- All India

Product Description

We have earned numerous accolades from clients for manufacturing and exporting an excellent stock of Top Entry Up Agitators. These agitators are widely used for mixing purposes in the industries of pharmaceuticals and chemicals. There are different models and specifications in which these agitators are offered to clients. Manufactured from the best quality of raw materials and components, these Top Entry Up Agitators are in confirmation with the industry standards and norms.

Features

- These agitators are best known for their sturdy designs and rust proof finish

- Can be also customized as per clients application requirements

- Tested on their finishing, these agitators are dispatched on time

Efficient Mixing for Varied Applications

Top Entry Up Agitators are crafted for both industrial and laboratory use, ensuring uniform and thorough mixing for a wide range of liquid processes. Their stainless steel construction guarantees longevity, while high capacity and adaptable voltage make them suitable for complex environments.

Durability and Electric Convenience

With corrosion-resistant stainless steel materials, these agitators endure rigorous operational conditions. Their electric-powered system offers hassle-free installation and consistent performance, supporting efficient workflow across industries.

Global Supply and Support

As an exporter, manufacturer, and supplier based in India, we provide comprehensive support and distribution for Top Entry Up Agitators worldwide. Each unit is backed by a one-year warranty, ensuring confidence and peace of mind for customers.

FAQs of Top Entry Up Agitators:

Q: How does a Top Entry Up Agitator work in an industrial or laboratory setting?

A: A Top Entry Up Agitator operates by rotating blades or paddles immersed in liquid, ensuring uniform mixing and agitation. Its electric motor powered by 220-240 Volts provides consistent performance for both large industrial tanks and smaller laboratory vessels.Q: What materials are used in the construction of these agitators?

A: These agitators are constructed from high-quality stainless steel, offering excellent resistance to corrosion, durability, and suitability for demanding environments.Q: When is the optimal time to use a Top Entry Up Agitator?

A: Top Entry Up Agitators are best used during the initial phase of any liquid blending or mixing operation, whether in chemical, pharmaceutical, or laboratory processes, to guarantee thorough agitation and homogeneity.Q: Where are these agitators commonly installed?

A: They are typically installed in industrial mixing tanks, reactors, or laboratory vessels where liquid mixing processes are essential. Their versatile design allows application across multiple settings.Q: What is the process for installation and operation of the agitator?

A: Installation involves mounting the agitator on the top entry of the tank and connecting it to a 220-240 Volt electric power supply. Once powered, operators can adjust speed and duration for optimal mixing based on specific application needs.Q: How does using a stainless steel agitator benefit industrial operations?

A: Stainless steel provides strong resistance to chemicals and corrosion, ensuring longer service life, maintenance efficiency, and high-performance mixing even under vigorous operational conditions.Q: What warranty and after-sales support do customers receive?

A: Each agitator comes with a one-year warranty, and as an exporter, manufacturer, and supplier from India, we offer ongoing technical support and assistance to our customers globally.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese